Wiper switch and washer switch. Intermittent wipe relay

FRONT See Wiper System and/or Washer System in the

Diagnosis and Testing section of this group before

testing the multi-function switch. For circuit descriptions

and diagrams, refer to 8W-53 - Wipers in Group

8W - Wiring Diagrams. WARNING: ON VEHICLES EQUIPPED WITH AN AIRBAG,

REFER TO GROUP 8M - PASSIVE RESTRAINT

SYSTEMS BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY. (1) Disconnect and isolate the battery negative

cable.

(2) Unplug the multi-function switch wire harness

connector from the multi-function switch.

(3) Using an ohmmeter, perform the switch continuity

checks at the switch terminals as shown in the

Multi-Function Switch Continuity chart (Fig. 2).

(4) If the switch fails any of the continuity checks,

replace the faulty switch. If the switch is OK, repair

the wiper system and/or washer system wire harness

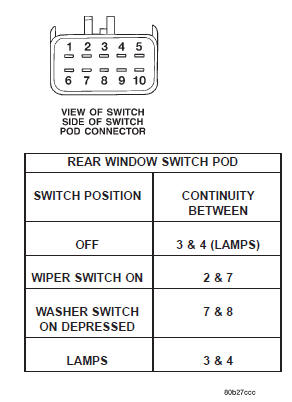

circuits as required. REAR Perform the diagnosis for the rear wiper system

and/or washer system as described in this group

before testing the rear wiper and washer switch. For

circuit descriptions and diagrams, see 8W-53 - Wipers

in Group 8W - Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL

INJURY. (1) Remove the lower bezel from the instrument

panel and unplug the rear window switch pod wire

harness connector.

(2) Using an ohmmeter, check the rear wiper and

washer switch continuity at the rear window switch

pod terminals as shown in the Rear Wiper Switch

and Washer Switch Continuity chart (Fig. 3).

(3) If the switch fails any of the continuity checks,

replace the faulty rear window switch pod. If the

switch is OK, repair the rear wiper system and/or

washer system wire harness circuits as required. For circuit descriptions and diagrams, refer to

8W-53 - Wipers in Group 8W - Wiring Diagrams. WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

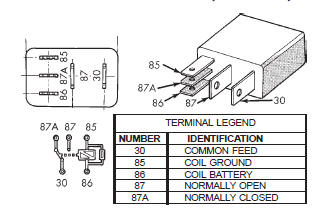

RELAY TEST The intermittent wipe relay (Fig. 4) is located in

the Power Distribution Center (PDC) in the engine

compartment. Refer to the PDC label for intermittent

wipe relay identification and location.

Remove the intermittent wipe relay from the PDC

as described in the Removal and Installation section

of this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (electromagnet)

should be 75 6 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test in the Diagnosis

and Testing section of this group. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST (1) The relay common feed terminal cavity (30) is

connected to the wiper (multi-function) switch. There

should be continuity between the cavity for relay terminal

30 and the two fused ignition switch output

circuit cavities of the multi-function switch wire harness

connector at all times. If OK, go to Step 2. If not

OK, repair the open circuit(s) to the multi-function

switch as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position.

There should be continuity between the cavity for

relay terminal 87A and the wiper park switch sense

circuit cavities of the wiper motor wire harness connector

and the 14-way Central Timer Module (CTM)

wire harness connector at all times. If OK, go to Step

3. If not OK, repair the open circuit(s) to the wiper

motor and CTM as required.

(3) The relay normally open terminal (87) is connected

to the common feed terminal (30) in the energized

position. There should be battery voltage at the

cavity for relay terminal 87 with the ignition switch

in the On or Accessory positions. If OK, go to Step 4.

If not OK, repair the open circuit to the ignition

switch as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. There should be battery

voltage at the cavity for relay terminal 86 with

the ignition switch in the On or Accessory positions.

If OK, go to Step 5. If not OK, repair the open circuit

to the ignition switch as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded by the

CTM to energize the relay and cycle the wiper motor.

Check for continuity between the cavity for relay terminal

85 and the intermittent wiper relay control circuit

cavity of the 14-way CTM wire harness

connector. There should be continuity. If OK, replace

the faulty base version CTM; or, use a DRB scan tool

and the proper Diagnostic Procedures manual for

diagnosis of the high-line version CTM. If not OK,

repair the open circuit to the CTM as required.Wiper switch and washer switch

Fig. 2 Multi-Function Switch Continuity

Fig. 2 Multi-Function Switch ContinuityIntermittent wipe relay

Fig. 3 Rear Wiper Switch and Washer Switch Continuity

Fig. 3 Rear Wiper Switch and Washer Switch Continuity Fig. 4 Intermittent Wipe Relay

Fig. 4 Intermittent Wipe Relay

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction