Refrigerant system service equipment. Vacuum system

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIGERANT

SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED,

BEFORE CONNECTING TO OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PERSONAL

INJURY. When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging station

that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for the proper care and use

of this equipment.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 9). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere. MANIFOLD GAUGE SET CONNECTIONS CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not compatible

and system damage will result. LOW PRESSURE GAUGE HOSE The low pressure hose (Blue with Black stripe)

attaches to the suction service port. This port is

located on the compressor manifold, directly over the

suction port of the compressor. HIGH PRESSURE GAUGE HOSE The high pressure hose (Red with Black stripe)

attaches to the discharge service port. This port is

located on the liquid line between the condenser and

the evaporator, near the front of the engine compartment. RECOVERY/RECYCLING/EVACUATION/CHARGING HOSE The center manifold hose (Yellow, or White, with

Black stripe) is used to recover, evacuate, and charge

the refrigerant system. When the low or high pressure

valves on the manifold gauge set are opened,

the refrigerant in the system will escape through this

hose.

1 - HIGH PRESSURE GAUGE 2 - VALVE 3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK

STRIPE) 4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE) 5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE) 6 - VALVE 7 - LOW PRESSURE GAUGE Vacuum control is used to operate the mode doors

in the heater-A/C housing. Testing of the heater-A/C

mode control switch operation will determine if the

vacuum, electrical, and mechanical controls are functioning.

However, it is possible that a vacuum control

system that operates perfectly at engine idle (high

engine vacuum) may not function properly at high

engine speeds or loads (low engine vacuum). This can

be caused by leaks in the vacuum system, or by a

faulty or improperly installed vacuum check valve.

A vacuum system test will help to identify the

source of poor vacuum system performance or vacuum

system leaks. Before starting this test, stop the

engine and make certain that the problem is not a

disconnected vacuum supply tube at the engine vacuum

source or at the vacuum reservoir.

Use an adjustable vacuum test set (Special Tool

C-3707-B) and a suitable vacuum pump to test the

heater-A/C vacuum control system. With a finger

placed over the end of the vacuum test hose probe

(Fig. 10), adjust the bleed valve on the test set gauge

to obtain a vacuum of exactly 27 kPa (8 in. Hg.).

Release and block the end of the probe several times

to verify that the vacuum reading returns to the exact 27 kPa (8 in. Hg.)

setting. Otherwise, a false

reading will be obtained during testing.

1 - VACUUM PUMP TOOL C-4289 2 - VACUUM TEST SET C-3707 3 - BLEED VALVE 4 - PROBE VACUUM CHECK VALVE (1) Remove the vacuum check valve that is to be

tested. The valves are located in the vacuum supply

tube (black) at the power brake booster on the left

side of the engine compartment, and in the heater

and air conditioner vacuum take-out of the vacuum

supply tube in the engine compartment. The vacuum

check valve must be removed in order to perform the

following tests. See Vacuum Check Valve in the

Removal and Installation section of this group for the

procedures.

(2) Connect the test set vacuum supply hose to the

heater-A/C control side of the valve. When connected

to this side of the check valve, no vacuum should

pass and the test set gauge should return to the 27

kPa (8 in. Hg.) setting. If OK, go to step Step 3. If

not OK, replace the faulty valve.

(3) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve. HEATER-A/C CONTROLS (1) Connect the test set vacuum probe to the heater-

A/C vacuum supply (black) tube in the engine

compartment. Position the test set gauge so that it

can be viewed from the passenger compartment.

(2) Place the heater-A/C mode control switch knob

in each mode position, one position at a time, and

pause after each selection. The test set gauge should return to the 27 kPa

(8 in. Hg.) setting shortly after

each selection is made. If not OK, a component or

vacuum line in the vacuum circuit of the selected

mode has a leak. See Locating Vacuum Leaks in the

Diagnosis and Testing section of this group. CAUTION: Do not use lubricant on the switch ports

or in the holes in the plug, as lubricant will ruin the

vacuum valve in the switch. A drop of clean water

in the connector plug holes will help the connector

slide onto the switch ports. LOCATING VACUUM LEAKS WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL

INJURY. (1) Disconnect the vacuum harness connector from

the back of the heater-A/C mode control switch on

the instrument panel.

(2) Connect the test set vacuum hose probe to each

port in the vacuum harness connector, one port at a

time, and pause after each connection (Fig. 11). The

test set gauge should return to the 27 kPa (8 in. Hg.)

setting shortly after each connection is made. If OK,

replace the faulty heater-A/C control. If not OK, go to

Step 3.

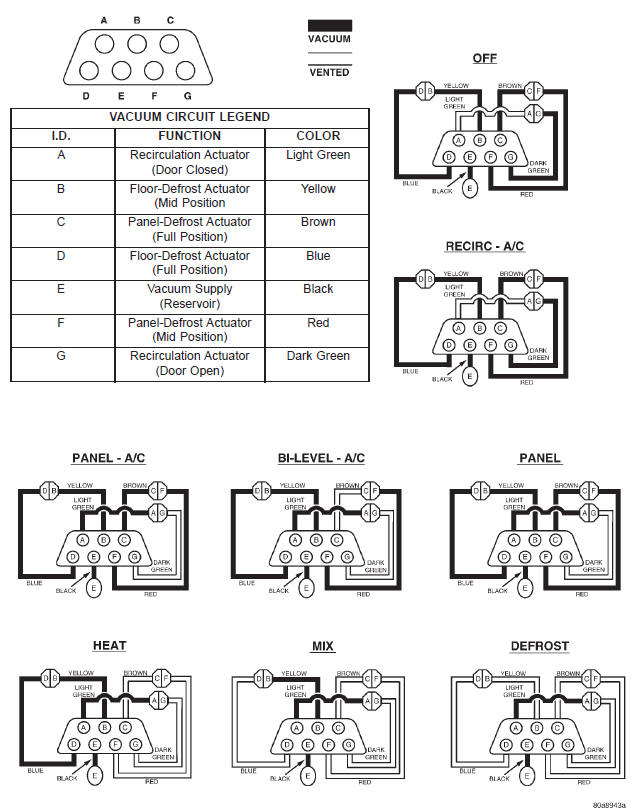

(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, see the Vacuum Circuits chart (Fig. 12).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reservoir)

on the other end of the leaking circuit. Instrument

panel disassembly or removal may be necessary

to gain access to some components. See the Removal

and Installation section of this group for more information.

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6) To locate a leak in a vacuum line, leave one

end of the line plugged and connect the test set hose

or probe to the other end of the line. Run your fingers

slowly along the line while watching the test set

gauge. The vacuum reading will fluctuate when your

fingers contact the source of the leak. To repair the

vacuum line, cut out the leaking section of the line.

Then, insert the loose ends of the line into a suitable

length of 3 millimeter (0.125 inch) inside diameter

rubber hose.

Refrigerant system service equipment

Fig. 9 Manifold Gauge Set - Typical

Fig. 9 Manifold Gauge Set - TypicalVacuum system

Fig. 10 Adjust Vacuum Test Bleed Valve

Fig. 10 Adjust Vacuum Test Bleed Valve Fig. 11 Vacuum Circuit Test

Fig. 11 Vacuum Circuit Test Fig. 12 Vacuum Circuits

Fig. 12 Vacuum Circuits

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction