Crankshaft main bearings. Oil pan 4x2 vehicle

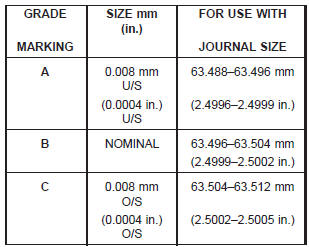

CRANKSHAFT MAIN BEARING SELECTION The main bearings are "select fit" to achieve proper

oil clearances. For main bearing selection, the crankshaft

position sensor target wheel has grade identification

marks stamped into it (Fig. 104). These marks

are read from left to right, corresponding with journal

number 1, 2, 3, 4 and 5. The crankshaft position

sensor target wheel is mounted to the number 8

counter weight on the crankshaft.

NOTE: Service main bearings color coded. These

color codes identify what size (grade) the bearing

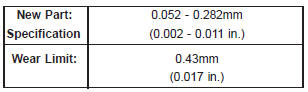

is. CHECKING CRANKSHAFT END PLAY (1) Mount a dial indicator to a stationary point at

front of engine. Locate the probe perpendicular

against nose of crankshaft (Fig. 105).

(2) Move the crankshaft all the way to the rear of

it's travel.

(3) Zero the dial indicator.

(4) Move the crankshaft all the way to the front of

it's travel and read the dial indicator. Refer to Crankshaft

End Play Specification Chart. REMOVAL (1) Drain the cooling system. Refer to COOLING

SYSTEM.

(2) Remove the upper fan shroud. Refer to procedure

in this section.

(3) Remove the throttle body resonator and air

inlet hose.

(4) Remove the intake manifold. Refer to procedure

in this section.

(5) Raise vehicle on hoist.

(6) Disconnect exhaust pipe at exhaust manifolds.

Refer to EXHAUST SYSTEM.

(7) Remove the structural dust cover (Fig. 106).

Refer to procedure in this section.

(8) Drain engine oil and remove oil filter.

(9) Position suitable jack under engine.

1 - LEFT CYLINDER HEAD 2 - RIGHT CYLINDER HEAD

1 - ADJUSTABLE PLIERS 2 - CAMSHAFT DOWEL (10) Remove both left and right side engine mount

through bolts (Fig. 107).

1 - TORQUE WRENCH 2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346 3 - LEFT CAMSHAFT SPROCKET 4 - RIGHT CAMSHAFT SPROCKET (11) Raise engine to provide clearance to remove

oil pan.

1 - REARMOST CRANKSHAFT COUNTER WEIGHT 2 - TARGET WHEEL 3 - MAIN BEARING SELECT FIT MARKINGS MAIN BEARING SELECTION CHART-4.7L

(12) Place blocks of wood between engine brackets

and lower mounts to provide stability to engine.

NOTE: Do not pry on oil pan or oil pan gasket.

Gasket is mounted to engine and does not come

out with oil pan.

(13) Remove the oil pan mounting bolts and oil

pan (Fig. 108).

(14) Unbolt oil pump pickup tube and remove tube

and oil pan gasket from engine. CRANKSHAFT END PLAY SPECIFICATION CHART

INSTALLATION (1) Clean the oil pan gasket mating surface of the

bedplate and oil pan.

(2) Position the oil pan gasket and pickup tube

with new o-ring. Install the mounting bolt and nuts.

Tighten bolt and nuts to 28 N*m (20 ft. lbs.).

(3) Position the oil pan and install the mounting

bolts. Tighten the mounting bolts to 15 N*m (11 ft.

lbs.) in the sequence shown (Fig. 108).

(4) Raise the engine and remove the blocks of

wood.

1 - LOCKNUT AND WASHER 2 - ENGINE MOUNT/INSULATOR 3 - THROUGH BOLT 4 - FRAME

(5) Lower engine and install both the left and

right side engine mount through bolts (Fig. 107).

Tighten the nuts to 68 N*m (50 ft. lbs.).

(6) Remove jack and install oil filter.

(7) Install structural dust cover.

(8) Install exhaust pipe onto exhaust manifolds.

(9) Lower vehicle.

(10) Install intake manifold.

(11) Install throttle body resonator and air inlet

hose.

(12) Install upper fan shroud.

(13) Fill cooling system.

(14) Fill engine oil.

(15) Start engine and check for leaks.Crankshaft main bearings

Oil pan 4x2 vehicle

Fig. 101 Timing Chain to Sprocket Alignment

Fig. 101 Timing Chain to Sprocket Alignment Fig. 102 Camshaft Sprocket Installation

Fig. 102 Camshaft Sprocket Installation Fig. 103 Tightening Right Side Cam Sprocket Retaining Bolt

Fig. 103 Tightening Right Side Cam Sprocket Retaining Bolt Fig. 104 Main Bearing Markings on Target Wheel

Fig. 104 Main Bearing Markings on Target Wheel

Fig. 105 Checking Crankshaft End Play-Typical

Fig. 105 Checking Crankshaft End Play-Typical

Fig. 106 Structural Dust Cover Removal / Installation

Fig. 106 Structural Dust Cover Removal / Installation Fig. 107 Engine Mount Through Bolt and Nut Removal / Installation

Fig. 107 Engine Mount Through Bolt and Nut Removal / Installation Fig. 108 Oil Pan Mounting Bolts and Oil Pan

Fig. 108 Oil Pan Mounting Bolts and Oil Pan

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction