Cylinder block

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

- The galley at the oil filter adaptor hole.

- The front and rear oil galley holes.

- The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealant with Teflon 592 to the threads of the front and rear oil galley plugs. Tighten the plugs to 34 N*m (25 ft. lbs.) torque.

Fig. 137 Checking Oil Pump Cover Flatness

Fig. 137 Checking Oil Pump Cover Flatness

1 - STRAIGHT EDGE

2 - FEELER GAUGE

3 - OIL PUMP COVER

Fig. 138 Measuring Outer Rotor Thickness

Fig. 138 Measuring Outer Rotor Thickness

Fig. 139 Measuring Inner Rotor Thickness

Fig. 139 Measuring Inner Rotor Thickness

Fig. 140 Measuring Outer Rotor Clearance in Housing

Fig. 140 Measuring Outer Rotor Clearance in Housing

1 - FEELER GAUGE

2 - OUTER ROTOR

Fig. 141 Measuring Clearance Between Rotors

Fig. 141 Measuring Clearance Between Rotors

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

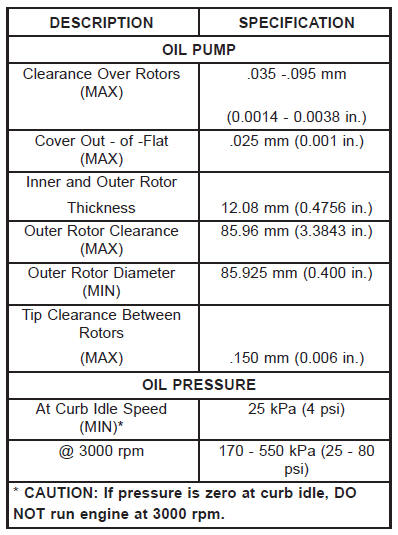

INSPECTION

(1) It is mandatory to use a dial bore gauge to measure each cylinder bore diameter. To correctly select the proper size piston, a cylinder bore gauge, capable of reading in 0.003 mm (.0001 in.) INCREMENTS is required. If a bore gauge is not available, do not use an inside micrometer (Fig. 143).

Fig. 142 Measuring Clearance Over Rotors

Fig. 142 Measuring Clearance Over Rotors

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 143 Bore Gauge-Typical

Fig. 143 Bore Gauge-Typical

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 49.5 MM (1-15/16 in)

(2) Measure the inside diameter of the cylinder bore at three levels below top of bore. Start perpendicular (across or at 90 degrees) to the axis of the crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise to the cylinder block near the top of the bore. Repeat the measurement near the middle of the bore, then repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller diameter from the larger diameter.

(5) Rotate measuring device 90 and repeat steps above.

(6) Determine out-of-roundness by comparing the difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025 mm (0.001 inch) and out-of-roundness does not exceed 0.025 mm (0.001 inch), the cylinder bore can be honed. If the cylinder bore taper or out- of-round condition exceeds these maximum limits, the cylinder block must be replaced. A slight amount of taper always exists in the cylinder bore after the engine has been in use for a period of time.

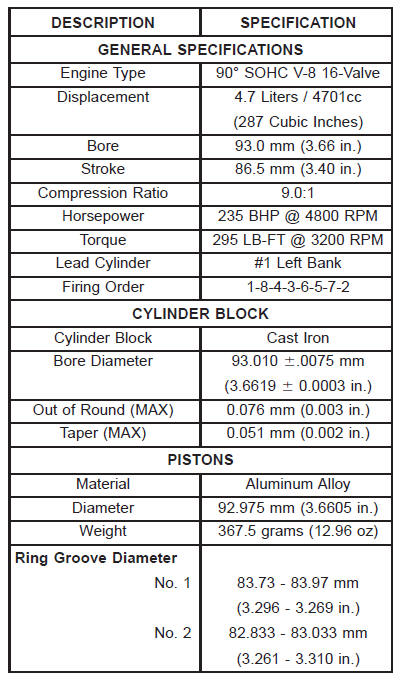

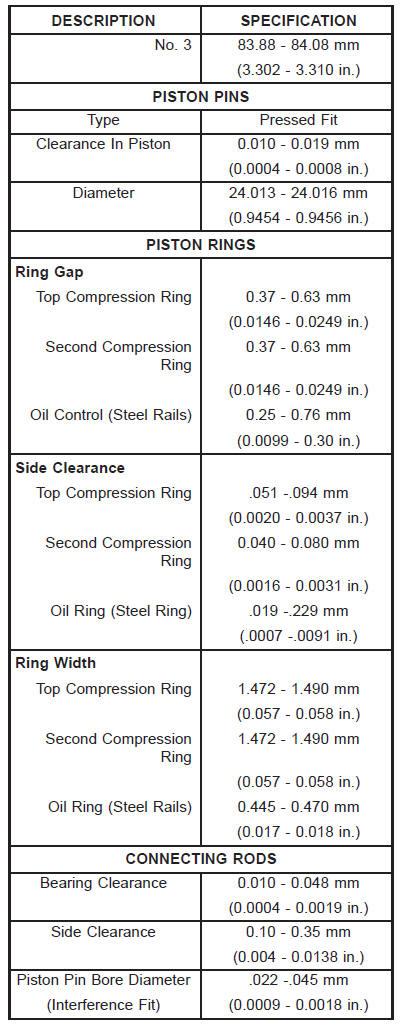

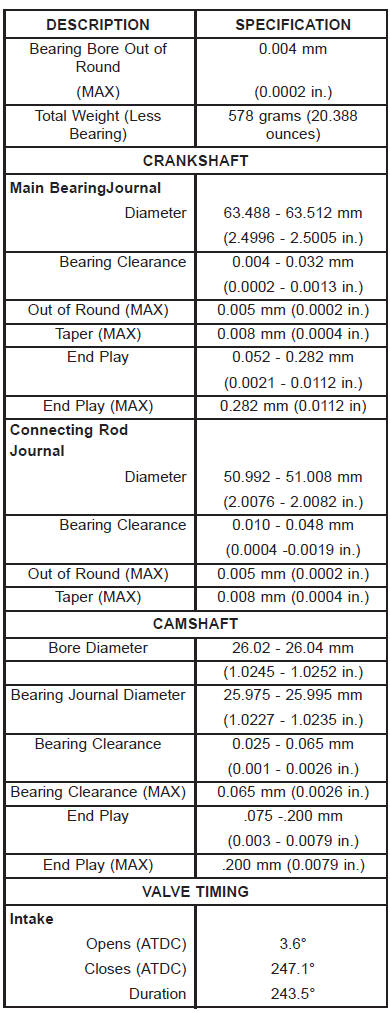

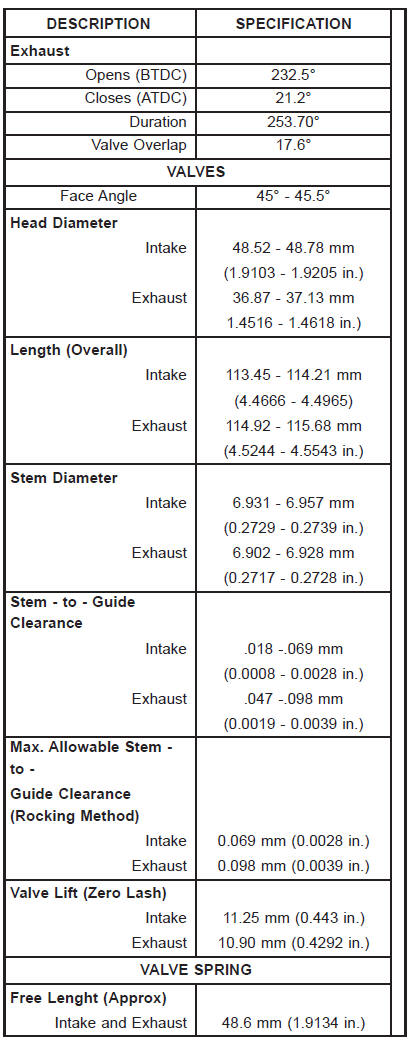

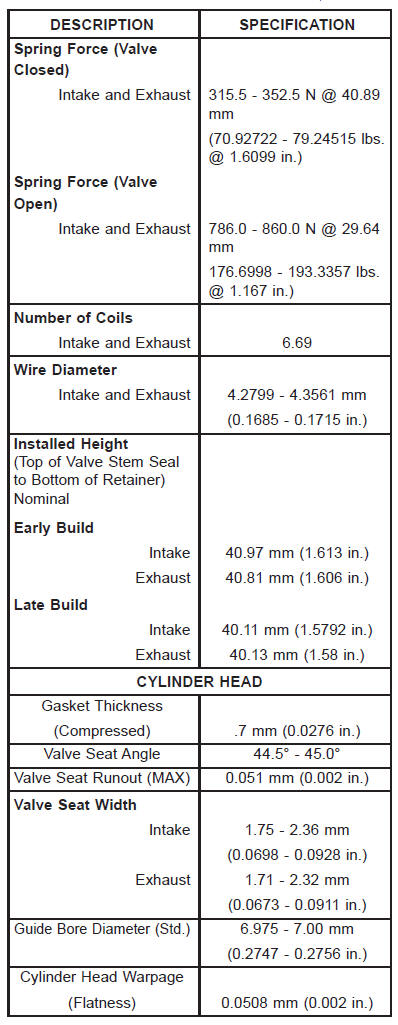

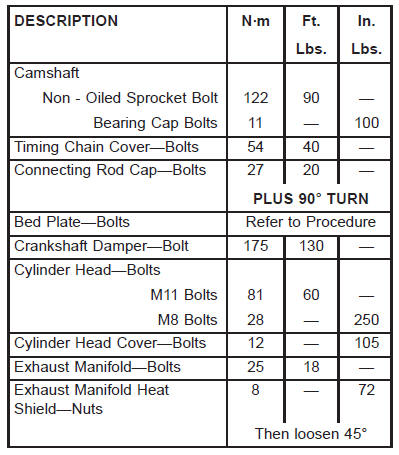

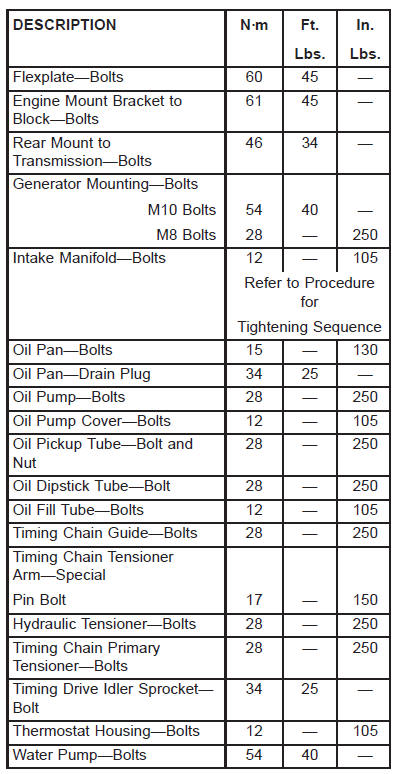

Specifications 4.7L engine

4.7L ENGINE

Torque

Special tools 4.7L engine

Spanner Wrench 6958

Spanner Wrench 6958

Adapter Pins 8346

Adapter Pins 8346

Engine Lifting Studs 8400

Engine Lifting Studs 8400

Engine Lift Fixture 8347

Engine Lift Fixture 8347

Front Crankshaft Seal Remover 8511

Front Crankshaft Seal Remover 8511

Front Crankshaft Seal Installer 8348

Front Crankshaft Seal Installer 8348

Handle C-4171

Handle C-4171

Rear Crankshaft Seal Installer 8349

Rear Crankshaft Seal Installer 8349

Rear Crankshaft Seal Remover 8506

Rear Crankshaft Seal Remover 8506

Connecting Rod Guides 8507

Connecting Rod Guides 8507

Crankshaft Damper Installer 8512

Crankshaft Damper Installer 8512

Puller 1026

Puller 1026

Crankshaft Damper Removal Insert 8513

Crankshaft Damper Removal Insert 8513

Chain Tensioner Wedge 8350

Chain Tensioner Wedge 8350

Chain Tensioner Pins 8514

Chain Tensioner Pins 8514

Secondary Chain Holder 8515

Secondary Chain Holder 8515

Remover, Rocker Arm 8516

Remover, Rocker Arm 8516

Valve Spring Compressor 8387

Valve Spring Compressor 8387

Idler Shaft Remover 8517

Idler Shaft Remover 8517

Valve Spring Compressor Adapters 8519

Valve Spring Compressor Adapters 8519

Valve Spring Tester C-647

Valve Spring Tester C-647

Dial Indicator C-3339

Dial Indicator C-3339

Valve Spring Compressor C-3422-B

Valve Spring Compressor C-3422-B

Bore Size Indicator C-119

Bore Size Indicator C-119

Oil Pressure Gauge C-3292

Oil Pressure Gauge C-3292

Piston Ring Compressor C-385

Piston Ring Compressor C-385

Pressure Tester Kit 7700

Pressure Tester Kit 7700

Bloc-Chek-Kit C-3685-A

Bloc-Chek-Kit C-3685-A

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction