Crankshaft main bearings

INSPECTION

Wipe the inserts clean and inspect for abnormal wear patterns and for metal or other foreign material imbedded in the lining. Normal main bearing insert wear patterns are illustrated (Fig. 31).

NOTE: If any of the crankshaft journals are scored, remove the engine for crankshaft repair.

Fig. 30 Checking Connecting Rod Side Clearance- Typical

Fig. 30 Checking Connecting Rod Side Clearance- Typical

Fig. 31 Main Bearing Wear Patterns

Fig. 31 Main Bearing Wear Patterns

1 - UPPER INSERT

2 - NO WEAR IN THIS AREA

3 - LOW AREA IN BEARING LINING

4 - LOWER INSERT

Inspect the back of the inserts for fractures, scrapings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Refer to Crankshaft in this section for procedure.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal with a micrometer. Measure at two locations 90 apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004 inch.) and maximum out of round is 0.005mm (0.002 inch). Compare the measured diameter with the jour-nal diameter specification (Main Bearing Fitting Chart). Select inserts required to obtain the specified bearing-to-journal clearance.

Install the crankshaft into the cylinder block. Refer to Crankshaft in this section for procedure.

CRANKSHAFT MAIN BEARING SELECTION

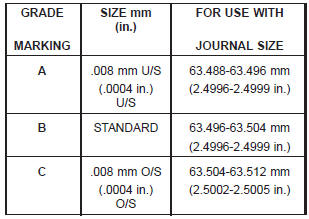

(1) Service main bearings are available in three grades. The chart below identifies the three service grades available.

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction