Blower motor. Blower motor relay

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO PASSIVE RESTRAINT SYSTEMS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY. For circuit descriptions and diagrams, refer to Air

Conditioning/Heater in Group 8W - Wiring Diagrams.

Possible causes of an inoperative front or rear blower

motor include: Possible causes of the front or rear blower motor

not operating in all speeds include: VIBRATION Possible causes of front or rear blower motor vibration

include: NOISE To determine that the rear blower is the source of

the noise, simply switch the blower motor from off to

on. There are no other moving parts involved in the

rear overhead A/C unit, which makes it simple to

identify the source of the noise. To verify that the front blower is the source

of the noise, unplug the

front blower motor wire harness connector and operate

the heater-A/C system. If the noise goes away,

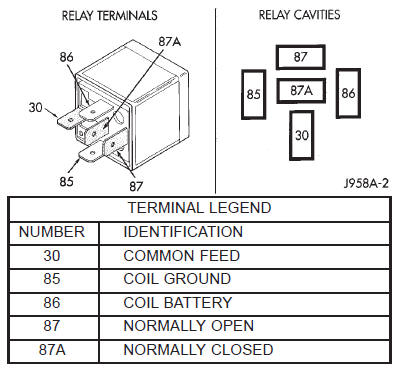

possible causes include: RELAY TEST The blower motor relay (Voltage Reduction Relay

or VRR) (Fig. 6) is mounted with a single screw

directly to the instrument panel's structural plastic

inside the glove box opening, next to the left-side

energy-absorbing bracket (Fig. 7). Remove the blower

motor relay to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (electromagnet)

should be 75 6 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test in the Diagnosis

and Testing section of this group. If not OK,

replace the faulty relay.

1 - BLOWER MOTOR RESISTOR CONNECTOR 2 - BLOWER MOTOR RELAY 3 - BLOWER MOTOR CONNECTOR 4 - GLOVE BOX LAMP CONNECTOR RELAY CIRCUIT TEST For circuit descriptions and diagrams, refer to Air

Conditioning/Heater in Wiring Diagrams.

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed directly from a fuse

in the Power Distribution Center (PDC), and should

be hot at all times. Check for battery voltage at the

PDC cavity for relay terminal 30. If OK, go to Step 2.

If not OK, repair the open circuit to the PDC fuse as

required.

(2) The relay normally closed terminal cavity (87A)

is not used for this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the blower motor. When the relay is

energized, terminal 87 is connected to terminal 30

and provides full battery current to the blower motor

feed circuit. There should be continuity between the

PDC cavity for terminal 87 and the blower motor

relay output circuit cavity of the blower motor wire

harness connector at all times. If OK, go to Step 4. If

not OK, repair the open circuit to the blower motor

as required.

(4) The coil battery terminal cavity (86) is connected

to the ignition switch. When the ignition

switch is placed in the On position, fused ignition

switch output is directed from a fuse in the junction

block to the relay electromagnetic coil to energize the

relay. There should be battery voltage at the PDC

cavity for relay terminal 86 with the ignition switch

in the On position. If OK, go to Step 5. If not OK,

repair the open circuit to the junction block fuse as

required.

(5) The coil ground terminal cavity (85) is connected

to ground. This terminal supplies the ground for the relay electromagnetic coil.

There should be

continuity between the PDC cavity for relay terminal

85 and a good ground at all times. If not OK, repair

the open circuit as required. ADDITIONAL RELAY CIRCUIT TESTINGBlower motor

Blower motor relay

Fig. 6 Blower Motor Relay

Fig. 6 Blower Motor Relay Fig. 7 Blower Motor Relay (VRR) Location

Fig. 7 Blower Motor Relay (VRR) Location

When the ignition switch is On, the voltage at that point should vary based on blower switch position.

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction