Description and operation. Diagnosis and testing

Steering system Description Power steering systems consist of: Operation The steering column shaft is attached to the gear

pinion. The rotation of the pinion moves the gear

rack from side-to-side. This lateral action of the rack

pushes and pulls the tie rods to change the direction

of the front wheels.

Power assist is provided by an engine mounted

hydraulic pump, (Fig. 1) and (Fig. 2) the pump supplies

hydraulic fluid pressure to the steering gear.

Some vehicles are equipped with an oil cooler.

1 - HYDRAULIC PUMP 2 - RACK AND PINION GEAR 3 - OIL COOLER

1 - HYDRAULIC PUMP 2 - RACK AND PINION GEAR 3 - OIL COOLER STEERING NOISE There is some noise in all power steering systems. One of the most common is

a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it's travel.

Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves

that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering

performance. 2. Noisy valve in power steering gear. 2. Replace steering gear. 2. Loose or damaged

suspension

components. 3. Internal gear noise. 4. Pressure hose in contact with other

components 5. Loose or damaged intermediate shaft or

column 2.

Inspect and repair suspension. 3. Replace steering gear. 4. Reposition hose. 5. Inspect and repair or replace. 2. Pressure hose in contact with other

components. 3. Internal pump noise. 2. Reposition hose. 3. Replace pump. 2. O-ring missing or damaged on hose

fitting. 3. Low fluid level. 4. Air leak between pump and reservoir. 5. Reservoir cap not installed correctly. 2. Replace o-ring. 3. Fill to proper level. 4. Repair as necessary. 5. Install reservoir cap correctly. 2. Wrong gear. 2. Verify gear. BINDING AND STICKING 2. Tire pressure. 3. Steering components (ball

joints/tie rod ends). 4. Loose belt. 5. Low pump pressure. 6. Column shaft coupler binding. 7. Steering gear worn. 2. Adjust tire pressure. 3 Inspect and repair as necessary. 4. Adjust or replace. 5. Pressure test and replace if

necessary. 6. Replace coupler. 7. Replace gear. INSUFFICIENT ASST. OR POOR RETURN TO CENTER 2. Low fluid level. 3. Loose belt. 4. Low pump pressure. 5. Internal gear leak. 2. Fill to proper level. 3. Adjust or replace. 4. Pressure test and repair as

necessary. 5. Replace gear. 2. Wheel alignment. 3. Lack of lubrication. 4. High friction in steering gear. 2. Align front end. 3. Inspect and lubricate suspension

compnents. 4. Replace gear. LOOSE STEERING AND VEHICLE LEAD 2. Worn or loose wheel bearings. 3. Steering gear mounting. 4. Gear out of adjustment. 5. Worn or loose steering coupler. 2. Inspect and repair or

adjust

bearings. 3. Tighten gear mounting bolts to

specification. 4. Replace gear. 5. Inspect and replace as

necessary. 2. Radial tire lead. 3. Brakes dragging. 4. Wheel alignment. 2. Rotate tires. 3. Repair as necessary. 4. Align front end. The following procedure is used to test the operation

of the power steering system on the vehicle. This

test will provide the gallons per minute (GPM) or

flow rate of the power steering pump along with the

maximum relief pressure. Perform test any time a

power steering system problem is present. This test

will determine if the power steering pump or power

steering gear is not functioning properly. The following

pressure and flow test is performed using Power

Steering Analyzer Tool kit 6815 (Fig. 3) and (Fig. 4)

Adapter Kit 6893. FLOW AND PRESSURE TEST (1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect pressure gauge hose from the Power

Steering Analyzer to Tube 6844.

(3) Connect Adapter 6826 to Power Steering Analyzer

test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect the tube to the pump hose fitting.

(6) Connect the power steering hose from the

steering gear to the adapter.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circulate

power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(9) Check fluid level, add fluid as necessary. Start

engine again and let idle.

1 - GAUGE HOSE 2 - TUBE 3 - ADAPTER FITTINGS 4 - ANALYZER (10) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

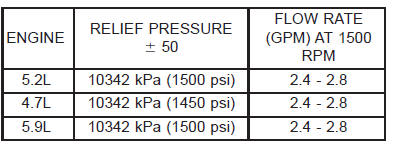

(11) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification, (refer to pump specification chart for

GPM) the pump should be replaced.

1 - TUBE 2 - ADAPTER FITTINGS 3 - ANALYZER 4 - GAUGE HOSE CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged. (12) Close valve fully three times and record highest

pressure indicated each time. All three readings

must be above specifications and within

345 kPa (50 psi) of each other. (13) Open the test valve and turn the steering

wheel to the extreme left and right positions three

times against the stops. Record the highest pressure

reading at each position. Compare readings to the

pump specifications chart. If pressures readings are

not within 50 psi of each other, the gear is leaking

internally and must be replaced. CAUTION: Do not force the pump to operate

against the stops for more than 2 to 3 seconds at a

time because, pump damage will result. PUMP SPECIFICATION Description and operation

Fig. 1 Steering Pump, Gear And Oil Cooler - 5.2L & 5.9L

Fig. 1 Steering Pump, Gear And Oil Cooler - 5.2L & 5.9L Fig. 2 Steering Pump, Gear And Oil Cooler - 4.7L

Fig. 2 Steering Pump, Gear And Oil Cooler - 4.7LDiagnosis and testing

Power steering system

CONDITION

POSSIBLE CAUSES

CORRECTION

OBJECTIONAL HISS OR

WHISTLE

1. Steering intermediate shaft to dash panel

seal.

1. Check and repair seal at dash

panel.

RATTLE OR CLUNK

1. Gear mounting bolts loose.

1. Tighten bolts to specification.

CHIRP OR SQUEAL

1. Loose belt.

1. Adjust or replace.

WHINE OR GROWL

1. Low fluid level.

1. Fill to proper level.

SUCKING AIR SOUND

1. Loose return line clamp.

1. Replace clamp.

SCRUBBING OR

KNOCKING

1. Wrong tire size.

1. Verify tire size.

CONDITION

POSSIBLE CAUSE

CORRECTION

DIFFICULT TO TURN WHEEL

STICKS OR BINDS

1. Low fluid level.

1. Fill to proper level.

CONDITION

POSSIBLE CAUSE

CORRECTION

HARD TURNING OR MOMENTARY

INCREASE IN TURNING EFFORT

1. Tire pressure.

1. Adjust tire pressure.

STEERING WHEEL DOES NOT

WANT TO RETURN TO CENTER

POSITION

1. Tire pressure.

1. Adjust tire pressure.

CONDITION

POSSIBLE CAUSE

CORRECTION

EXCESSIVE PLAY IN STEERING

WHEEL

1. Worn or loose suspension or

steering components.

1. Inspect and repair as necessary.

VEHICLE PULLS OR LEADS TO

ONE SIDE.

1. Tire Pressure.

1. Adjust tire pressure.

Power steering flow and pressure

Fig. 3 Analyzer With Tube and Adapter For 5.2L & 5.9L

Fig. 3 Analyzer With Tube and Adapter For 5.2L & 5.9L Fig. 4 Analyzer With Tube and Adapter For 4.7L

Fig. 4 Analyzer With Tube and Adapter For 4.7L

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction