A/c performance

The air conditioning system is designed to provide the passenger compartment with low temperature and low humidity air. The evaporators, located in the heater-A/C housing on the dash panel below the instrument panel and in the rear overhead A/C unit housing above the headliner, are cooled to temperatures near the freezing point. As warm damp air passes through the cooled evaporators, the air transfers its heat to the refrigerant in the evaporator tubes and the moisture in the air condenses on the evaporator fins. During periods of high heat and humidity, an air conditioning system will be more effective in the recirculation mode (Max-A/C). With the system in the recirculation mode, only air from the passenger compartment passes through the evaporator.

As the passenger compartment air dehumidifies, the air conditioning system performance levels improve.

Humidity has an important bearing on the temperature of the air delivered to the interior of the vehicle.

It is important to understand the effect that humidity has on the performance of the air conditioning system. When humidity is high, the evaporator has to perform a double duty. It must lower the air temperature, and it must lower the temperature of the moisture in the air that condenses on the evaporator fins. Condensing the moisture in the air transfers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can absorb from the air. High humidity greatly reduces the ability of the evaporator to lower the temperature of the air.

However, evaporator capacity used to reduce the amount of moisture in the air is not wasted. Wringing some of the moisture out of the air entering the vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their air conditioning system on humid days. A performance test is the best way to determine whether the system is performing up to standard. This test also provides valuable clues as to the possible cause of trouble with the air conditioning system.

Review the Service Warnings and Precautions in the General Information section near the front of this group before performing this procedure. The air temperature in the test room and in the vehicle must be a minimum of 21 C (70 F) for this test.

(1) Connect a tachometer and a manifold gauge set.

(2) Set the heater-A/C mode control switch knob in the recirculation mode (Max-A/C) position, the temperature control knob in the full cool position, and the blower motor switch knob in the highest speed position.

(3) Start the engine and hold the idle at 1,000 rpm with the compressor clutch engaged. If the compressor clutch does not engage, see the A/C Diagnosis chart in the Diagnosis and Testing section of this group.

(4) The engine should be at operating temperature.

The doors and windows must be closed and the hood must be mostly closed.

CAUTION: Never insert a thermometer probe into the outlet for the optional rear overhead A/C unit.

Failure to observe this caution could result in damage to the rear blower wheel and/or the thermometer.

(5) Insert a thermometer in the driver side center A/C (panel) outlet for testing of the front unit, or hold a thermometer near the center outlets in the headliner for testing of the rear unit. Operate the engine for five minutes.

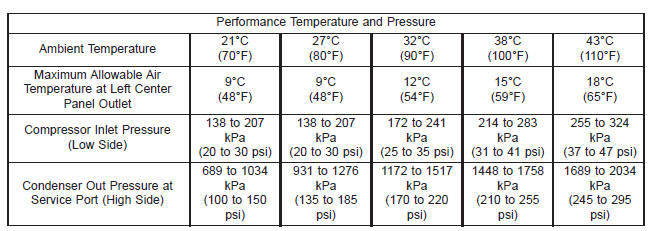

(6) With the compressor clutch engaged, record the panel outlet or left center outlet discharge air temperature, the condenser out pressure (high side), and the compressor inlet pressure (low side). The compressor clutch may cycle, depending upon the ambient temperature and humidity. If the clutch cycles, use the readings obtained before the clutch disengaged.

(7) Compare the discharge air temperature reading to the Performance Temperature and Pressure chart. If the temperature reading is high for the rear unit, see Refrigerant System Leaks in the Diagnosis and Testing section of this group, and Refrigerant System Charge in the Service Procedures section of this group. If the temperature reading is high for the front unit, clamp off both heater hoses (inlet and outlet), wait five minutes and record the temperature again. Compare the second reading to the Performance Temperature and Pressure chart. If the temperature reading is now OK, see Temperature Control Cable in the Removal and Installation section and in the Adjustments section of this group. If the temperature reading is still too high, see Refrigerant System Leaks in the Diagnosis and Testing section of this group, and Refrigerant System Charge in the Service Procedures section of this group.

(8) Compare the discharge (high side) and suction (low side) pressure readings to the Performance Temperature and Pressure chart. If the pressures are abnormal, suction pressure is not normal, see the A/C Diagnosis chart in the Diagnosis and Testing section of this group.

| A/C Diagnosis | ||

| CONDITION | POSSIBLE CAUSE | CORRECTION |

| RAPID COMPRESSOR CLUTCH CYCLING (TEN OR MORE CYCLES PER MINUTE). | 1. Low refrigerant system

charge.

2. Faulty electronic cycling clutch switch. 3. Faulty Powertrain Control Module (PCM). |

1. See Refrigerant System Leaks in the Diagnosis and

Testing section of this group. Test the refrigerant system

for leaks. Repair, evacuate and charge the refrigerant

system, if required.

2. See Electronic Cycling Clutch Switch in the Diagnosis and Testing section of this group. Test the electronic cycling clutch switch and replace, if required. 3. Refer to the proper Diagnostic Procedures manual for testing of the PCM. Test the PCM and replace, if required. |

| EQUAL PRESSURES, BUT THE COMPRESSOR CLUTCH DOES NOT ENGAGE. | 1. No refrigerant in the

refrigerant system.

2. Faulty fuse. 3. Faulty compressor clutch coil. 4. Faulty compressor clutch relay. 5. Faulty electronic cycling clutch switch. 6. Faulty low pressure cut-off switch. 7. Faulty high pressure cut-off switch. 8. Faulty Powertrain Control Module (PCM). 9. Faulty heater-A/C control. |

1. See Refrigerant System Leaks in the Diagnosis and

Testing section of this group. Test the refrigerant system

for leaks. Repair, evacuate and charge the refrigerant

system, if required.

2. Check the fuses in the Power Distribution Center and the junction block. Repair the shorted circuit or component and replace the fuses, if required. 3. See Compressor Clutch Coil in the Diagnosis and Testing section of this group. Test the compressor clutch coil and replace, if required. 4. See Compressor Clutch Relay in the Diagnosis and Testing section of this group. Test the compressor clutch relay and relay circuits. Repair the circuits or replace the relay, if required. 5. See Electronic Cycling Clutch Switch in the Diagnosis and Testing section of this group. Test the electronic cycling clutch switch and replace, if required. 6. See Low Pressure Cut-Off Switch in the Diagnosis and Testing section of this group. Test the low pressure cut-off switch and replace, if required. 7. See High Pressure Cut-Off Switch in the Diagnosis and Testing section of this group. Test the high pressure cut-off switch and replace, if required. 8. Refer to the proper Diagnostic Procedures manual for testing of the PCM. Test the PCM and replace, if required. 9. See Heater-A/C Control in the Diagnosis and Testing section of this group. Test the heater-A/C control and replace, if required. |

| NORMAL PRESSURES, BUT A/C PERFORMANCE TEST AIR TEMPERATURES ARE TOO HIGH. | 1. Excessive refrigerant

oil in system.

2. Temperature control cable improperly installed or faulty. 3. Blend-air door inoperative, obstructed or sealing improperly. |

1. See Refrigerant Oil Level in the Service Procedures

section of this group. Recover the refrigerant from the

refrigerant system and inspect the refrigerant oil content.

Restore the refrigerant oil to the proper level, if required. 2. See Temperature Control Cable in the Removal and Installation and Adjustments sections of this group. Inspect the temperature control cable for proper routing, operation and adjustment. Repair as required. 3. See Heater-A/C Housing Door in the Removal and Installation section of this group. Inspect the blend-air door for proper operation and sealing and correct, if required. |

| LOW SIDE PRESSURE IS NORMAL OR SLIGHTLY LOW, AND HIGH SIDE PRESSURE IS TOO LOW. | 1. Low refrigerant system

charge.

2. Refrigerant flow through the evaporator coil is restricted. 3. Faulty compressor |

1. See Refrigerant System Leaks in the Diagnosis and

Testing section of this group. Test the refrigerant system

for leaks. Repair, evacuate and charge the refrigerant

system, if required.

2. See Evaporator Coil in the Removal and Installation section of this group. Replace the restricted evaporator coil, if required. 3. See Compressor in the Diagnosis and Testing section of this group. Replace the compressor, if required. |

| LOW SIDE PRESSURE IS NORMAL OR SLIGHTLY HIGH, AND HIGH SIDE PRESSURE IS TOO HIGH. | 1. Condenser air flow

restricted.

2. Inoperative cooling fan. 3. Faulty expansion valve. 4. Refrigerant system overcharged. 5. Air in the refrigerant system. 6. Engine overheating. |

1. Check the condenser for damaged fins, foreign objects

obstructing air flow through the condenser fins, and

missing or improperly installed air seals. Refer to Group 7

- Cooling System for more information on air seals.

Clean, repair, or replace components as required. 2. Refer to Group 7 - Cooling System for more information. Test the cooling fan and replace, if required. 3. See Expansion Valve in the Diagnosis and Testing section of this group. Replace the faulty expansion valve, if required. 4. See Refrigerant System Charge in the Service Procedures section of this group. Recover the refrigerant from the refrigerant system. Charge the refrigerant system to the proper level, if required. 5. See Refrigerant System Leaks in the Diagnosis and Testing section of this group. Test the refrigerant system for leaks. Repair, evacuate and charge the refrigerant system, if required. 6. Refer to Group 7 - Cooling System for more information. Test the cooling system and repair, if required. |

| LOW SIDE PRESSURE IS TOO HIGH, AND HIGH SIDE PRESSURE IS TOO LOW. | 1. Accessory drive belt

slipping.

2. Faulty compressor. |

1. Refer to Group 7 - Cooling System for more

information. Inspect the accessory drive belt condition

and tension. Tighten or replace the accessory drive belt, if

required.

2. See Compressor in the Diagnosis and Testing section of this group. Replace the compressor, if required. |

| LOW SIDE PRESSURE IS TOO LOW, AND HIGH SIDE PRESSURE IS TOO HIGH. | 1. Restricted refrigerant

flow through the

refrigerant lines.

2. Restricted refrigerant flow through the expansion valve. 3. Restricted refrigerant flow through the condenser. 4. Restricted refrigerant flow through the filter-drier. |

1. See Liquid Line and Suction and Discharge Line in the

Removal and Installation section of this group. Inspect the

refrigerant lines for kinks, tight bends or improper routing.

Correct the routing or replace the refrigerant line, if required. 2. See Expansion Valve in the Diagnosis and Testing section of this group. Replace the restricted expansion valve, if required. 3. See Condenser in the Removal and Installation section of this group. Replace the restricted condenser, if required. 4. See Filter-Drier in the Removal and Installation section of this group. Replace the restricted filter-drier, if required. |

Dodge Durango (DN) 1998-2003 Service Manual

- Lubrication and Maintenance

- Suspension

- Differential and Driveline

- Brakes

- Cooling System

- Battery

- Starting Systems

- Charging System

- Ignition System

- Instrument Panel Systems

- Audio Systems

- Horn Systems

- Speed Control System

- Turn Signal and Hazard Warning Systems

- Wiper and Washer Systems

- Lamps

- Passive Restraint Systems

- Electrically Heated Systems

- Power Distribution System

- Power Lock Systems

- Vehicle Theft/Security Systems

- Power Seat System

- Power Window Systems

- Power Mirror Systems

- Chime/Buzzer Warning Systems

- Overhead Console Systems

- Engine

- Exhaust System

- Frame and Bumpers

- Fuel System

- Steering

- Transmission and Transfer Case

- Tires and Wheels

- Body

- Heating and Air Conditioning

- Emission Control Systems

- Introduction